The UCA leads a pioneering project for the sustainable repair of metal components through WAAM additive manufacturing 12 November 2025

The initiative integrates 3D scanning, wire arc deposition, and CNC machining to optimize industrial processes and promote the ecological and digital transition in Andalusia.

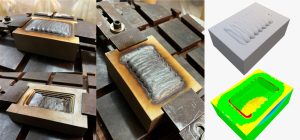

The University of Cádiz has launched a research project aimed at transforming the processes of repairing metallic components in the Andalusian industry by combining advanced digitization technologies and additive manufacturing. The initiative, led by Professor Nuria Baladés Ruiz, proposes a comprehensive approach that combines 3D scanning, the Wire Arc Additive Manufacturing (WAAM) technique, and CNC machining to extend the lifespan of industrial parts, reduce waste, and improve productive efficiency.

This project involves a multidisciplinary team of researchers affiliated with the Higher Technical School of Engineering of Algeciras at UCA: David Sales, Juan María Terrones, Antonio Illana, Luis Segovia, Leticia Moreno, and Blanca Silva, with the collaboration of Aida Estévez from the University of Seville. With a duration of two years, this initiative is co-funded by the European Regional Development Fund (ERDF) and the Ministry of University, Research and Innovation of the Andalusian Government, through the ERDF Operational Program Andalusia 2021-2027.

Likewise, it is important to indicate that this research is being conducted at the Smart Manufacturing Lab, located at the new UCA-SEA Innovation Center on the Bahía de Algeciras Campus. It will allow for the generation of standardized procedures for the repair of medium and large-sized metal components, with special attention to strategic sectors of the province. The use of WAAM (a layer-by-layer deposition technology using arc and wire) offers advantages such as reduced time and costs, efficient material utilization, and a smaller carbon footprint compared to conventional manufacturing or part replacement methods.

On the other hand, it should be noted that the project includes the precise digital reconstruction of damaged components through 3D scanning, advanced analysis of printing trajectories, and validation of repairs using microstructural characterization techniques and mechanical tests. Similarly, it includes an economic feasibility study and a life cycle assessment to quantify the environmental impact of repair versus the manufacture of new spare parts, promoting a circular economy model aligned with the principles of Industry 4.0.

The work line is supported by the experience of the UCA research team, which has a solid track record in additive manufacturing, material characterization, and knowledge transfer to the industrial sector. This initiative aims to strengthen collaboration with leading companies in the Campo de Gibraltar and the Bay of Cádiz, contributing to a more sustainable production model and the ecological and digital transition of the Andalusian industrial fabric.

For this reason, this group of researchers wants to invite “interested industries to contact us to propose specific needs for the repair of medium-large format industrial components made of weldable metal alloys and to collaborate in the development of this innovative project.” Thus, interested entities can send their proposals to the email address cimalab@uca.es.